Process Control

The RotoCure System Manager functions on the Windows operating system to provide unprecedented control features for RotoSpeed rotational molding machines.

New features include:

- Real-time KPI’s

- Arm & Plate balance program

- Multi-layer (shot) programming

- Rocking Program to build wall thickness in specific areas

- Arm Orientation

- Live Machine Graphics

- IRT programming integral on oven & cooler Set-up Screens

- Detailed Tending & Production reporting

Ferry’s InfraRed Thermometry™ (IRT) provides continuous process control for heating and cooling cycles on Ferry RotoSpeed rotational molding machines. IRT enhances the repeatability of cure, cycle to cycle.

InfraRed Thermometry™ (IRT) for rotational molding machines is available exclusively from Ferry Industries, Inc.

The RotoLog™ 5.0 Wi-Fi is the latest version of the highly successful system. RotoLog identifies the time at which the powder has melted in the mold, shows the peak internal air temperature (PIAT) inside the mold, the time at which solidification accurs in the cooling cycle and the time at which de-molding can take place. By establishing an optimum cycle time, waste is minimized and production is maximized.

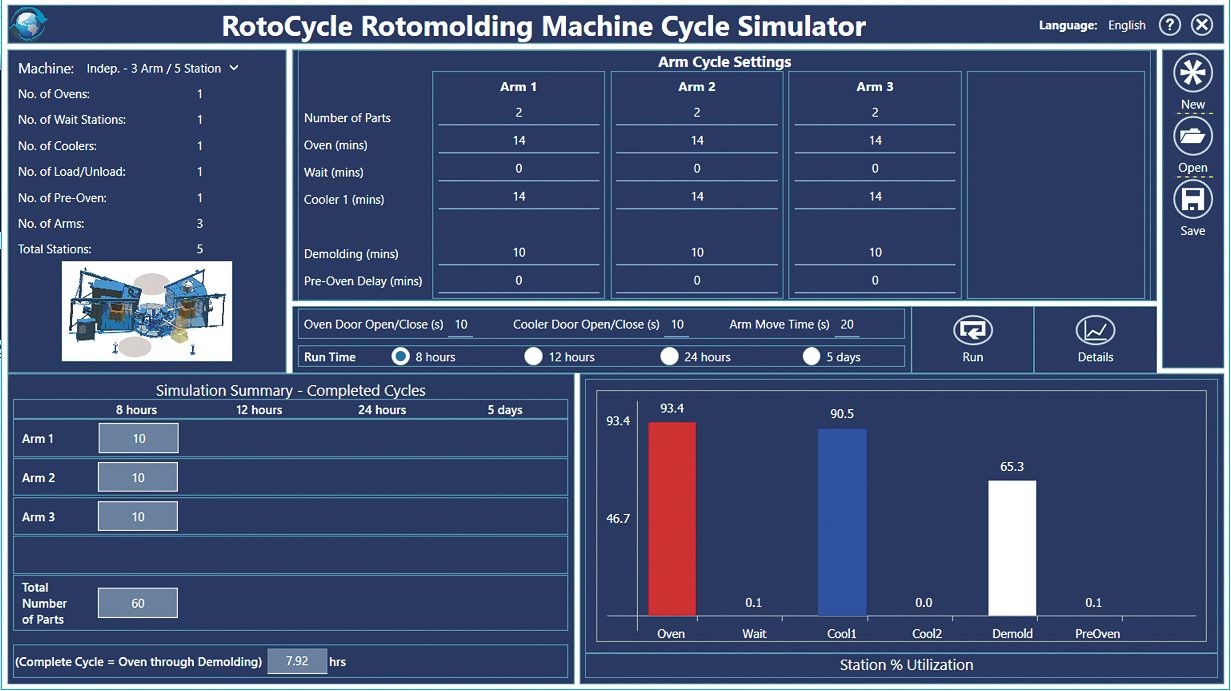

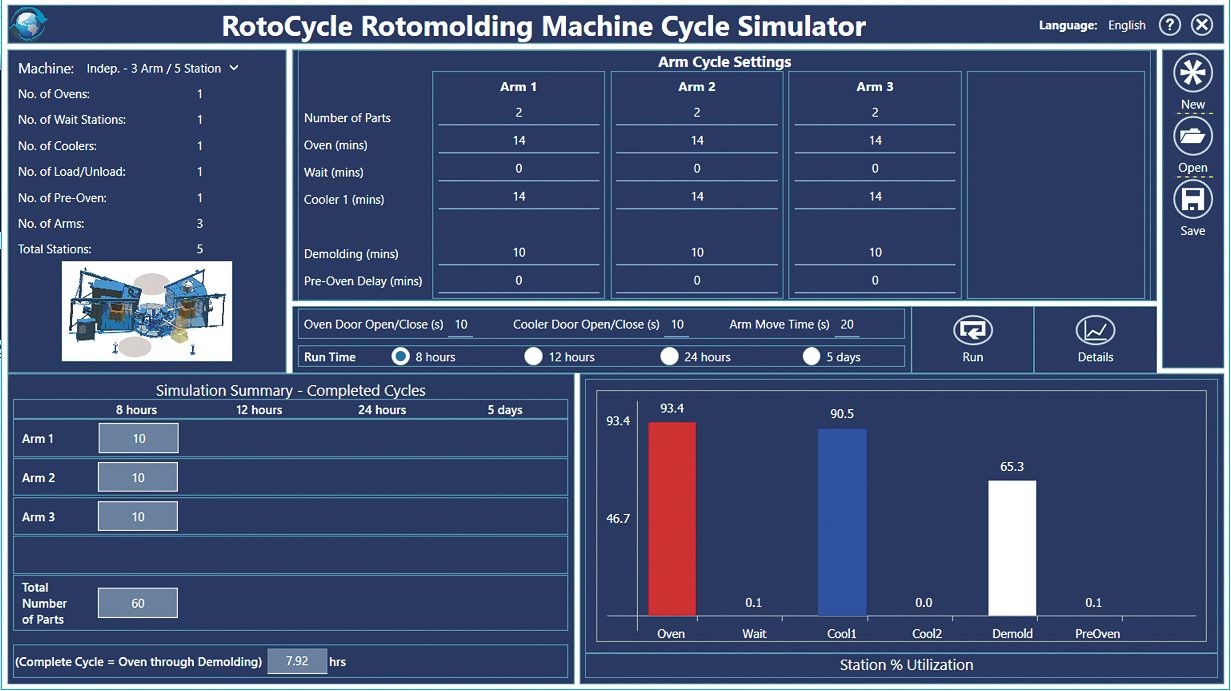

Desktop Software Program For Rotomolding Cycle Simulation.

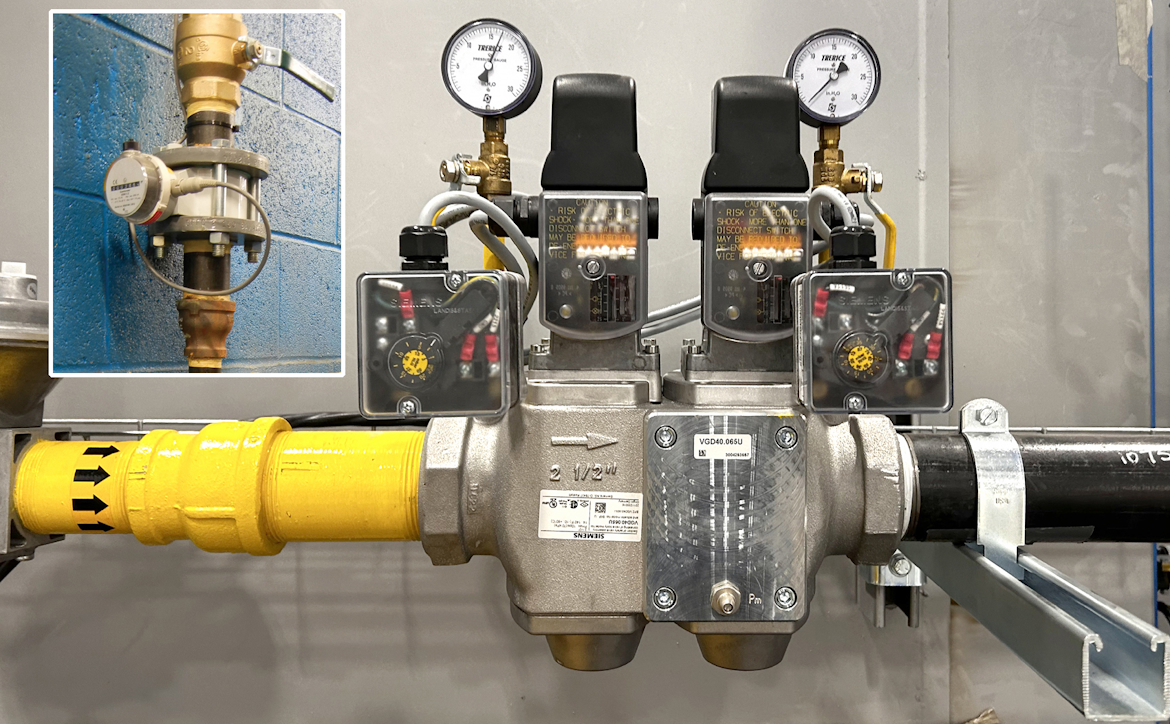

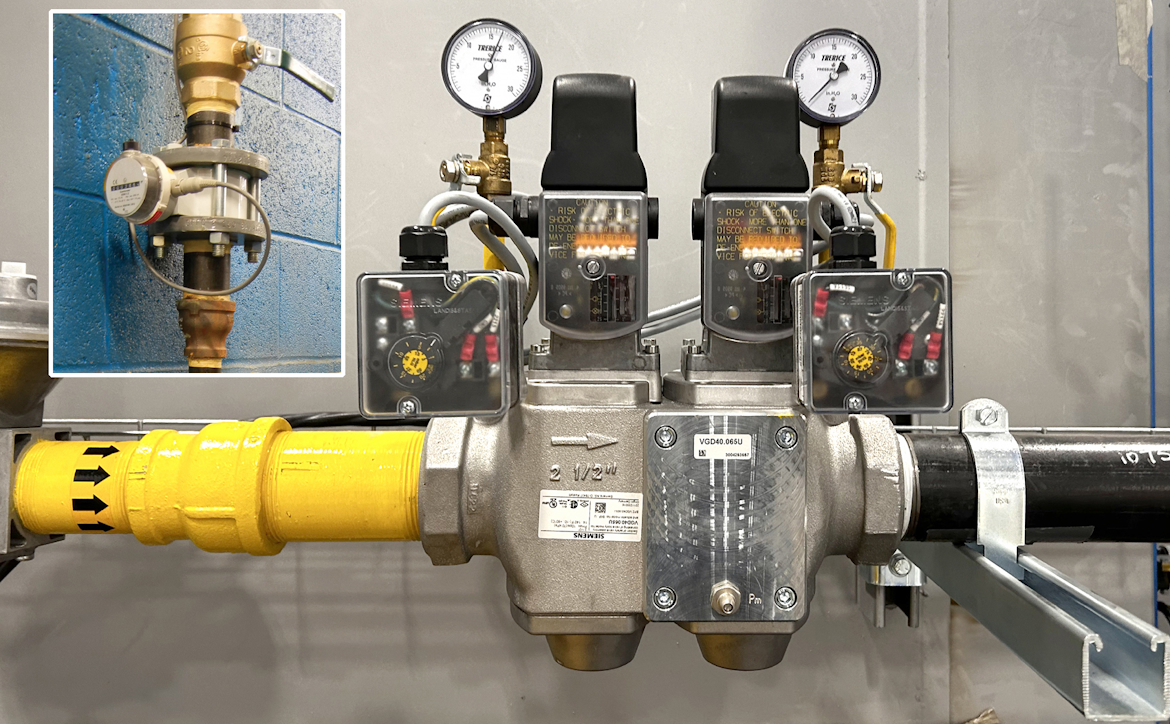

Gas Meters

Cooling Fans

Cooling is a essential part of Rotational molding. Ferry has fans engineered to each type and size of rotational molding machine. In chamber fans with optional water mist, water recovery chamber catch pans with recirculation pumps, open area moveable stand cooling fans with & without water mist and more.