RotoSpeed rotational molding machines are available in numerous standard models. These are complemented by an outstanding lineup of process controls, high intensity mixers, powder dispensing systems, and other support products and solutions. Please review our product offerings below. If you have any questions, please contact us.

When Performance Counts!

Independent-Arm Carousel Machines

Ferry Industries, Inc. pioneered the four-arm, five-station independent-arm carousel system: a game-changing advancement in rotational molding.

Our RotoSpeed™ independent-arm machines feature fully-independent carts and shares a common load-bearing track assembly. These carts index around a central pivot and operate across multiple stations for heating, cooling, and servicing. The shared track system ensures smooth indexing, while the modular design allows unmatched flexibility in layout, capacity, and process optimization.

Fixed-arm Turret Carousel Machines

Ferry’s RotoSpeed™ fixed-arm turret machines deliver efficient, high-output processing in a proven platform, trusted by molders worldwide.

Each turret machine has all arms mounted to a central indexing chassis, indexing in unison through the full production cycle – heating, cooling, and unloading. Available in three-arm and four-arm configurations, these machines are ideal when station times are balanced and consistent.

All models accommodate both straight and offset arms, giving you layout flexibility with the simplicity of fixed-arm sequencing. This classic, proven design promotes efficient labor use, fast setup, and consistent performance.

Carousel Machines

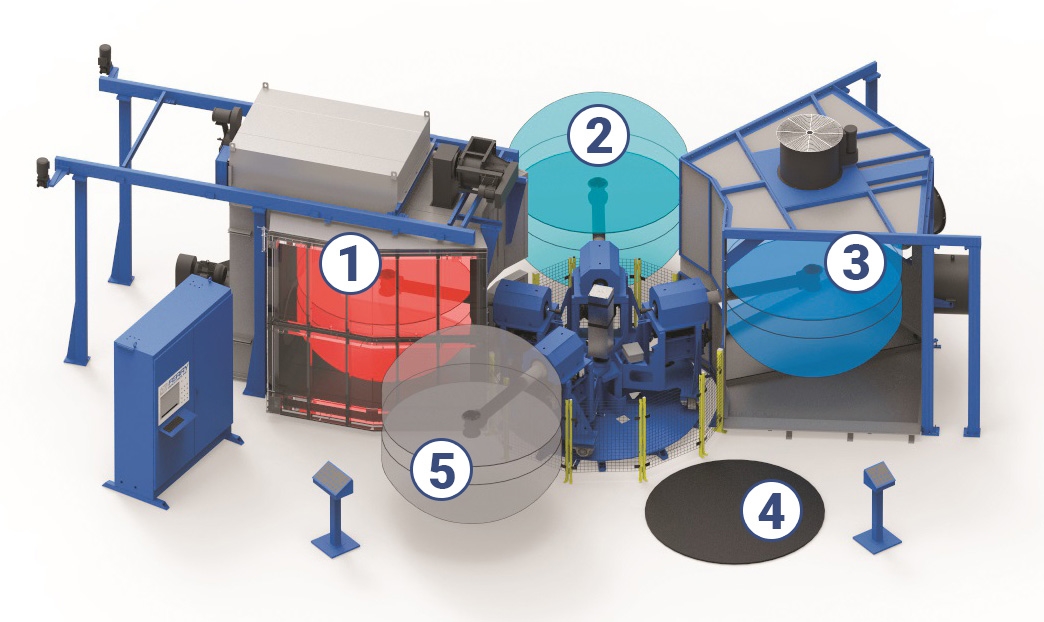

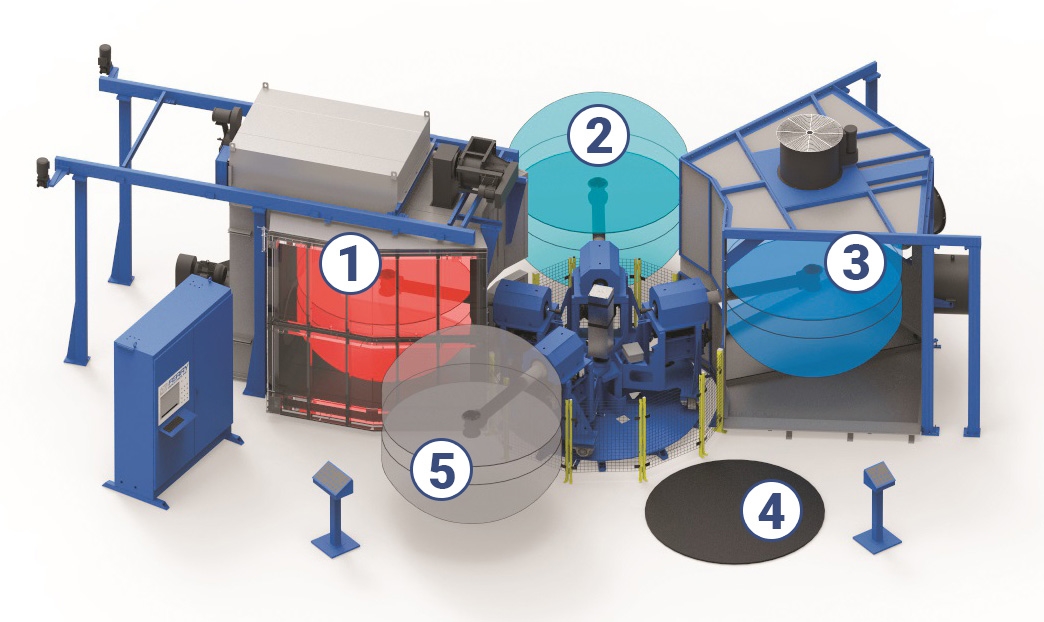

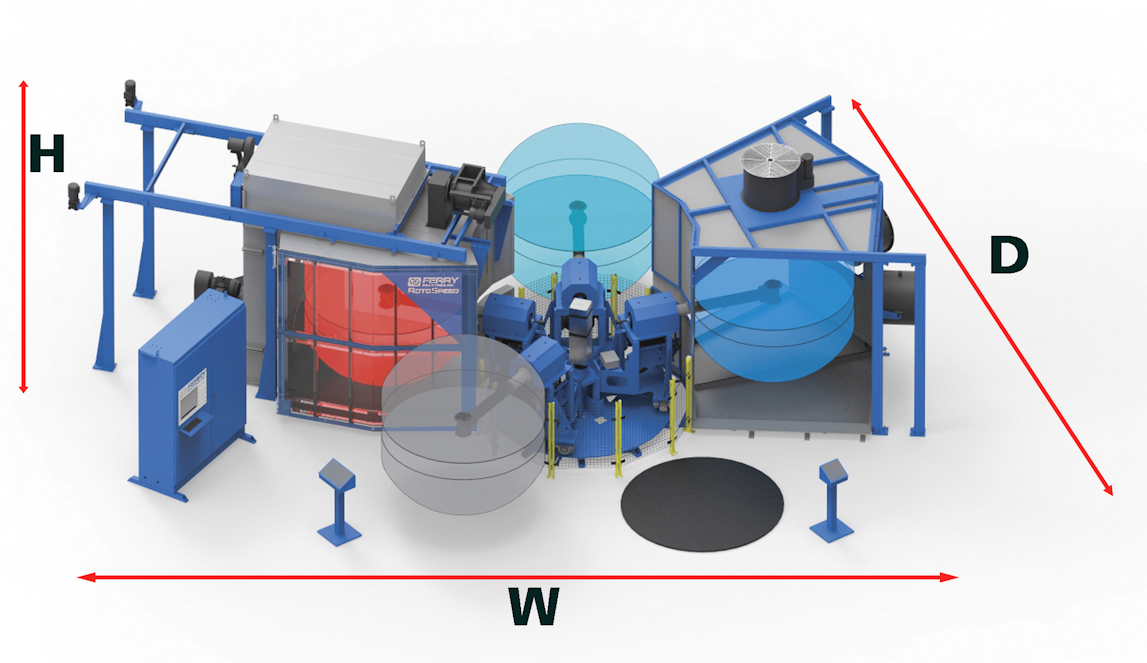

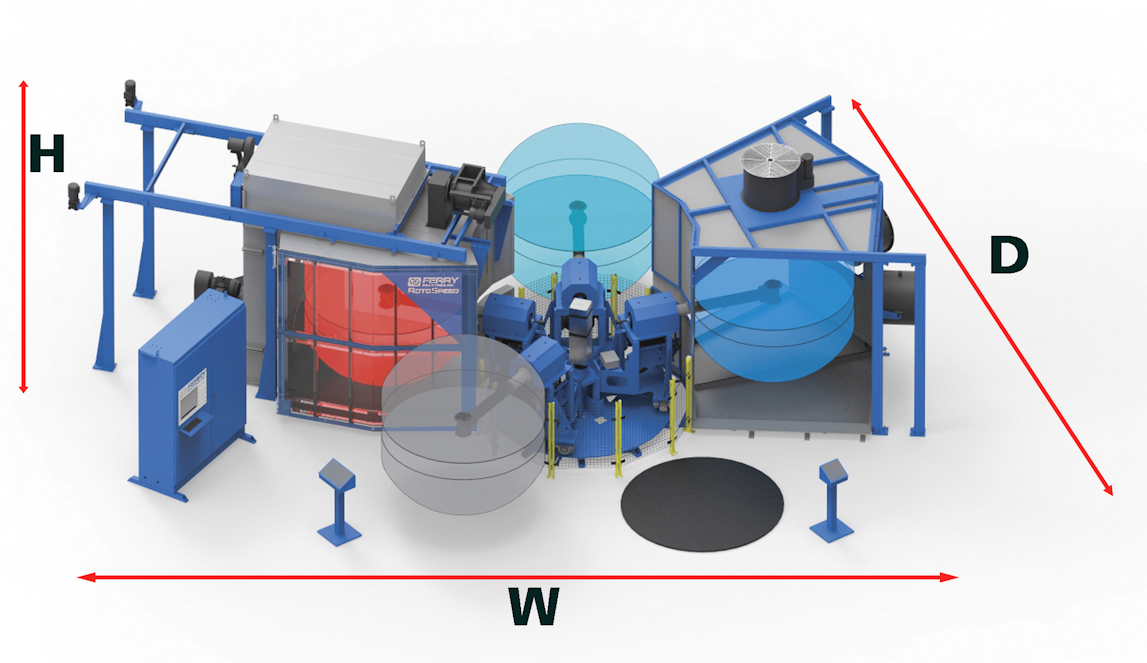

Independent-Arm Machines

Ferry Industries, Inc., pioneered the four-arm, five-station independent-arm carousel machine for the rotational molding industry. RotoSpeed independent-arm machines (with each arm on a separate cart) provide a multiple-station arrangement for heating, cooling, and servicing. Each cart indexes about a center pivot post and shares a common load-bearing track.

Fixed-Arm Turret Machines

Fixed-arm turret machines provide increased processing capabilities while promoting the most efficient use of labor. Ferry Industries has expanded the capabilities of the traditional turret machine to meet the production needs of the user. Six direct-drive RotoSpeed turret-style configurations are available.

In-Line Shuttle Machines

Ferry’s In-Line Shuttle machines are a smart, simple solution that are built for flexibility — especially in facilities where a narrow footprint is available. The In-line shuttle utilizes a central oven with up to two carts/arms, one on either side, that alternate shuttling in and out of the oven. Each cart operates with a dedicated combination cooling/service station.

In-line Suttle machines are ideal for varying production volumes, wide variety of part sizes, and provides solutions for both simple and complex molded parts. Separate cycle programming per arm gives you the freedom to run different molds, different cycles — all in one system.

Rocking Oven Machines

Ferry’s Rocking Oven machines are engineered for molding long, narrow products — such as cylindrical tanks, kayaks, lamp posts, or multi-part assemblies mounted on a spindle. Each system includes one oven station, up to two cooling/load-unload stations. The mold or mold group mounts directly to a rotating spindle — which spins on a continuous 360° rotation, while the rocking motion tilts left and right up to 45° in each direction.

RotoCure software provides multi-step rotation and rocking programming for consistent wall thickness.

Laboratory Machines

Laboratory machines are smaller single-arm machines for prototyping and developing resins, colors, additives, and other work where process development and testing/sampling are needed. Laboratory machines are ideal for small spaces and short production runs.

Laboratory style machines have many of the same features and systems as Ferry’s larger RotoSpeed production machines, including our industry leading RotoCure software which can be customizable to be unique for any application.

Specs & Tech

Important materials on RotoSpeed rotational molding machines are available for download here. If you need additional resources, please contact us.

Specifications subject to change without notice.

Specs & Tech Topics

Carousel