Support Equipment

Upgrade Controls – Increase Performance

Breathe new life into your current Ferry RotoSpeed Machines for Increased Performance.

Areas that you may want to improve include, Machine control system, Infrared Thermometry (IRT), Oven burner & gas control, Cooling chamber or Open-Air cooling adding water mist or water recovery, Arm & Cart additions or improvements.

Adding Operator work platforms, Dispensing systems & powder Mixing are other areas that can be added after a machine is in service and improve worker safety & productivity.

Arms & Carts – Add more or a different style of arm

Need to increase production or fit a single mold that fills the oven?

Adding an additional Arm & Cart or having a Offset-arm that can be swapped onto an existing cart can often resolve production needs.

Oven Components

Ferry’s RotoSpeed oven burners are robust and efficient.

All ovens are designed & engineered to provide maximum performance, efficiency & durability.

Cooling Components

High-volume, energy efficient fans with programmable water mist in cooler chamber or as stand alone floor units for maximum cooling effectiveness.

- Add fans to cooling chamber backwall

- Low and Tall freestanding moveable fans

- All fans tilt for focused area cooling

- All Fans can have water mist

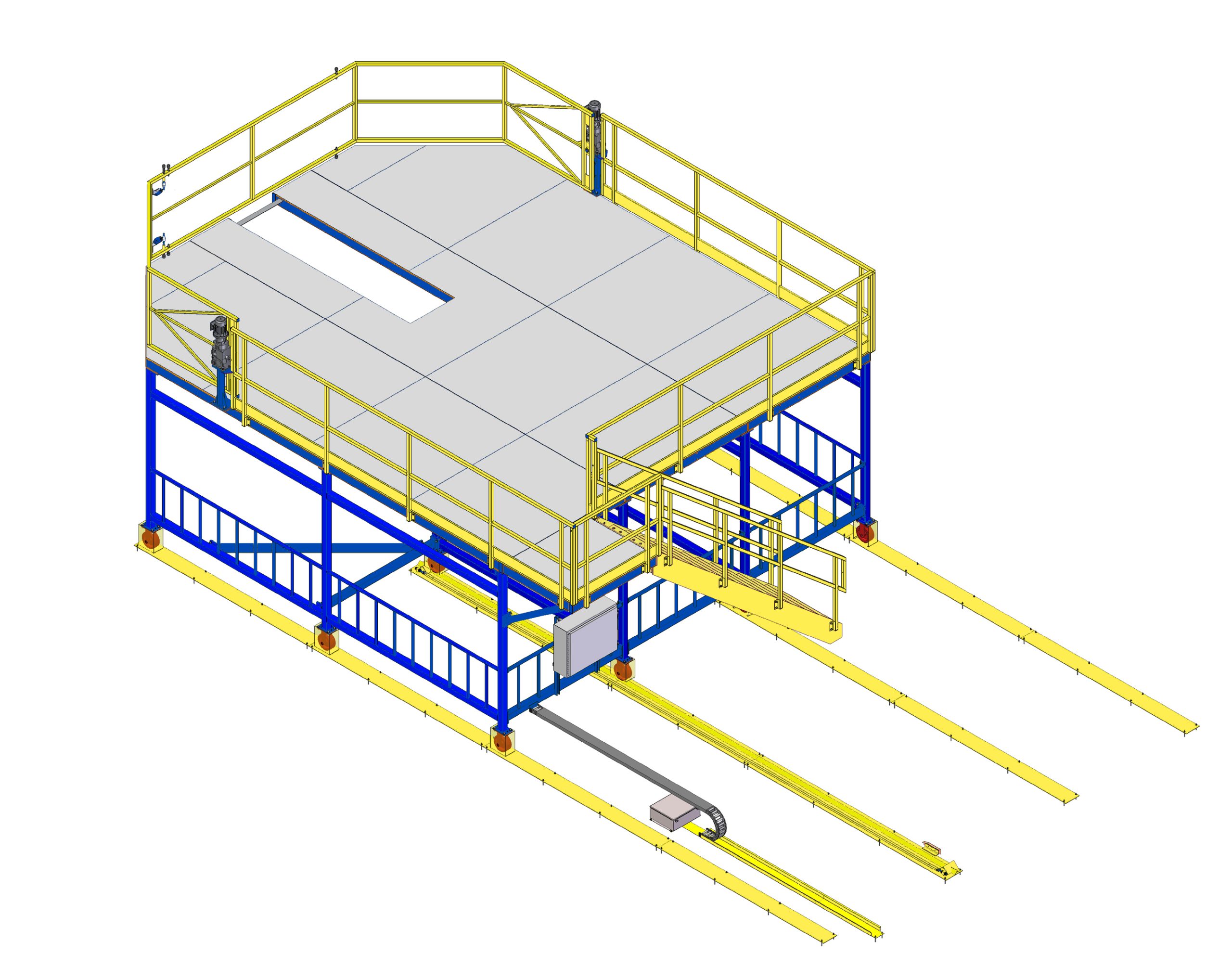

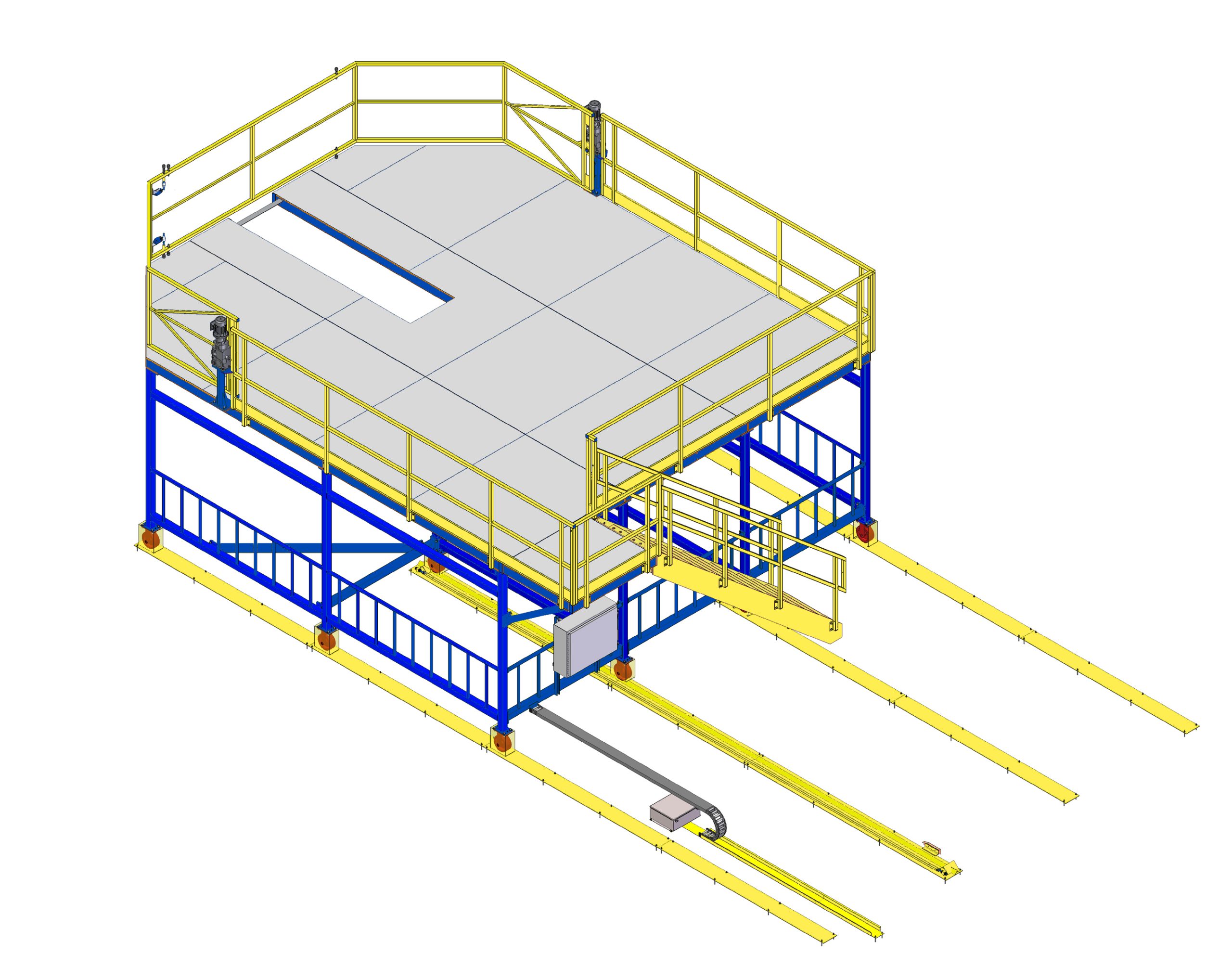

Operator Work Platforms

Ferry’s work platforms provide stable, elevated work space for operators, materials, hand tools and equipment used to service rotational molding machine arms and molds. Ferry manufactures platforms for Fixed-Arm Turret Carousels, Independent-Arm Carousels and In-Line Shuttle Machines. Ferry makes single-station and dual-station configurations as well as manually-operated and powered configurations. Part transfer slides are also available.

Special platform designs are available on request. Ferry’s platforms help quicken turnaround at the load/unload stations.

Arm & Plate Remotes

Increase efficiency and reduce operator fatigue during the load and unload cycles of your molding operations. These remote controls provide arm & plate jogging in the operators’ hands, allowing them to rotate major & minor axis position quickly for mold servicing and part unloading.

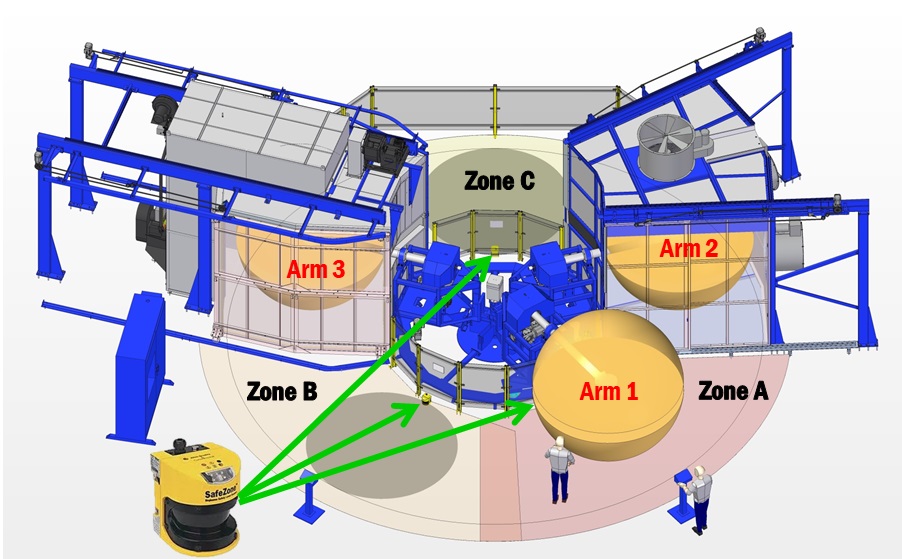

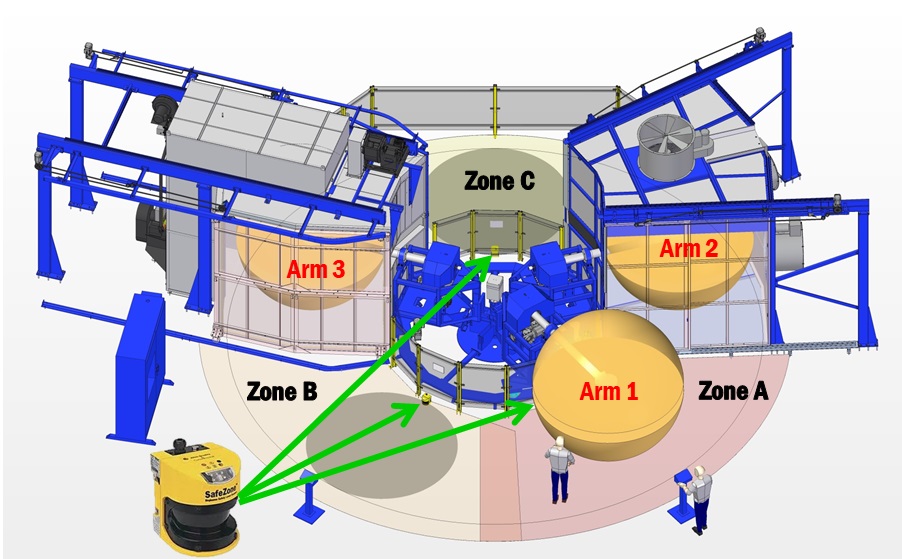

Safety Components & Systems

Ferry RotoSpeed machines have standard and optional safety systems and components improve the work environment.

Safety is paramount for great work environments!

Powder Dispensers

The RotoLoad Powder Dispensing System is an automatic powder weighing and dispensing system that will quickly, safely and cleanly dispense your powdered PE directly into the molds that are mounted on your rotational molding machine.

Material Mixers

High-Intensity Mixers help rotational molders blend various materials to required specifications. Special attention has been given to the bowl and lid interior surface finish, as well as quick loading and fast and complete discharge of material. Some models provide cycle control based on time and/or temperature to ensure fast and thorough blending without incurring material melt point.

Bar Code Label Printer

Bar code label printers are available as an option to your Ferry RotoSpeed machine. The printer is integrated into RotoCure. There is a standard label size available with standard bar coded and text information that prints out.