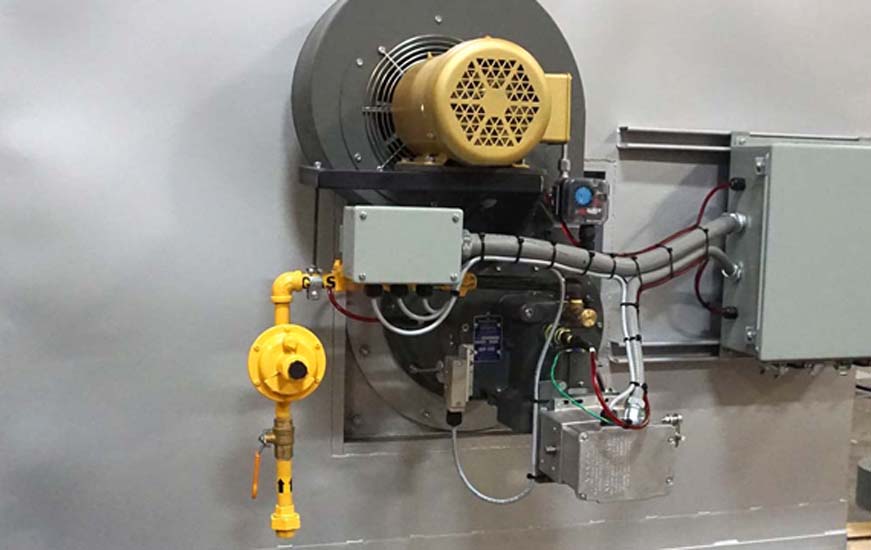

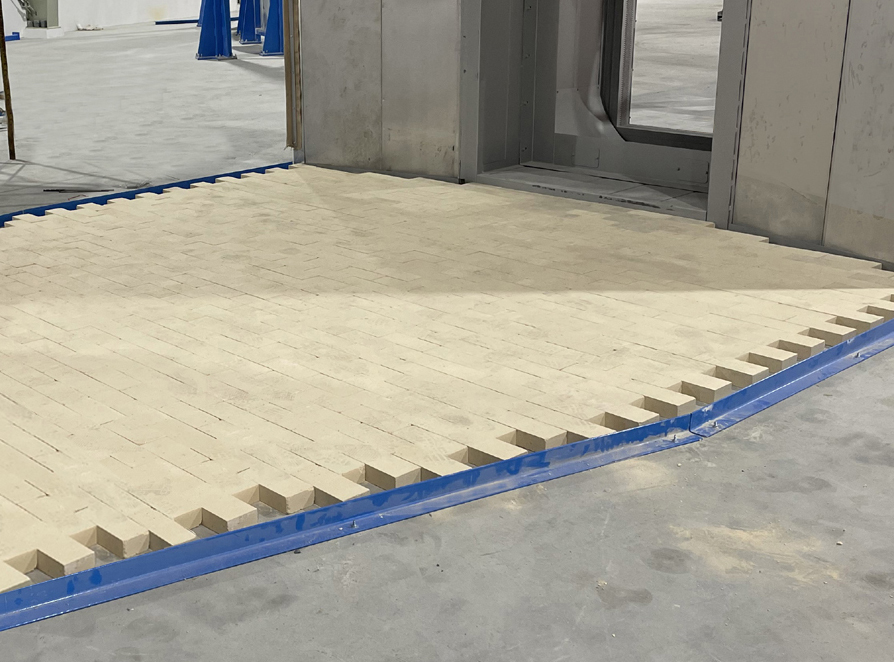

Burners

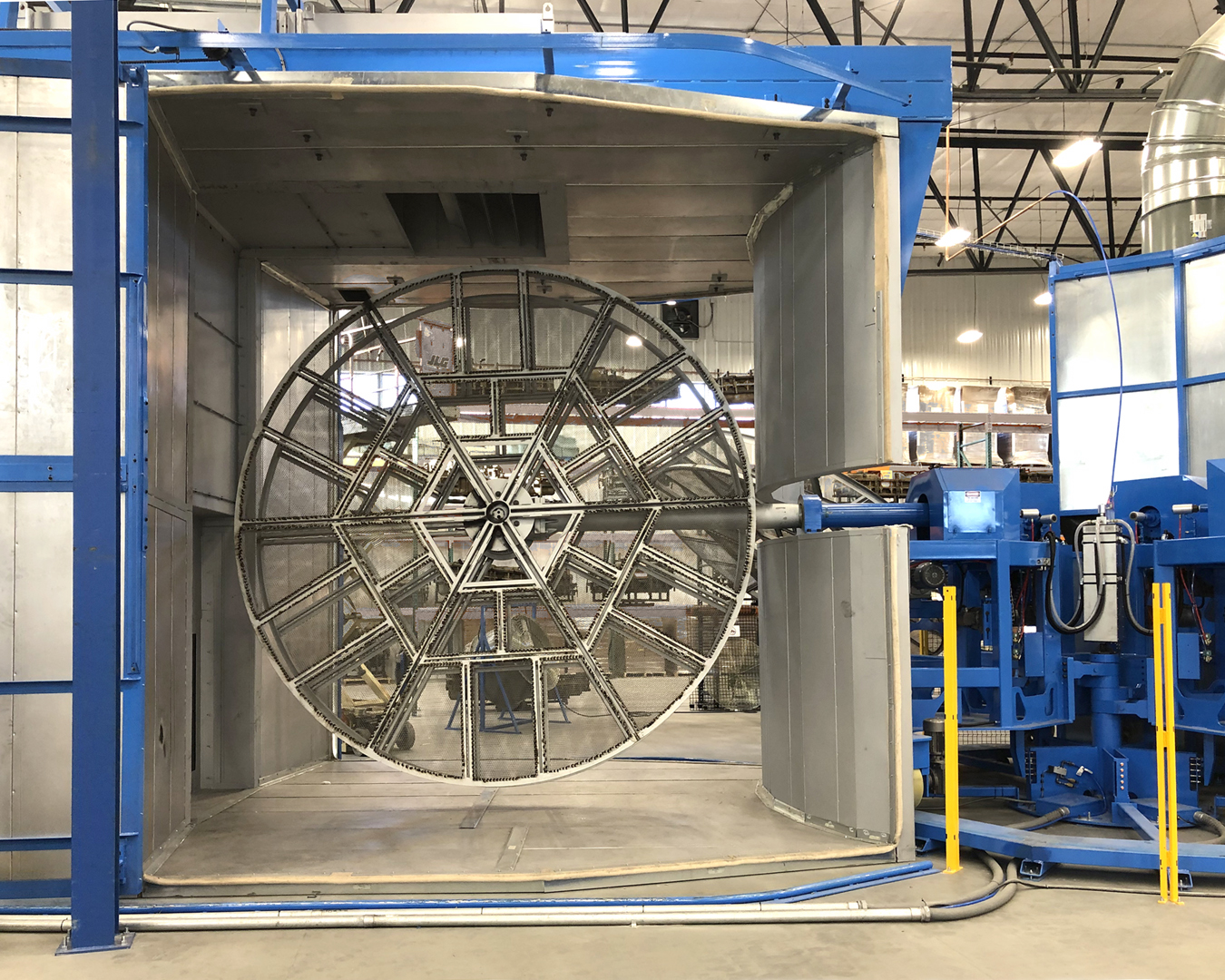

Ferry Industries, Inc., pioneered the four-arm, five-station independent-arm carousel machine for the rotational molding industry. RotoSpeed independent-arm machines (with each arm on a separate cart) provide a multiple-station arrangement for heating, cooling, and servicing. Each cart indexes about a center pivot post and shares a common load-bearing track.

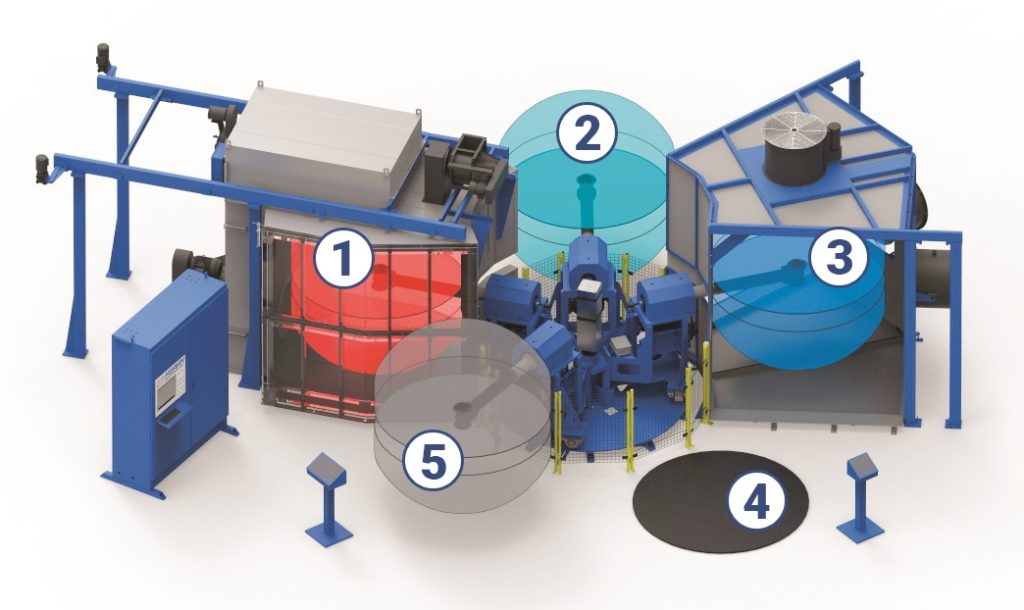

The floor plan provides five process stations: 1. Oven 2. Pre-cool or Intermediate 3. Cooling 4. Unload 5. Load

- Oven

- Pre-cool or Intermediate

- Cooling

- Unload

- Load

These machines can be purchased with only one arm/cart. Up to three more may be added without mechanical modifications to the existing machine. Double ovens or double cooling stations are available initially or can be added later due to the modular layout of the RotoSpeed independent-arm concept. Custom design for these machines is available.

Models Available

| Model Name | # of Arma | Swing Ranges | Capacities | |

|---|---|---|---|---|

| Model 1 Here | 1 | 55″ – 239″ (1440 – 6125 mm) | 1000 – 12000 lbs (454 – 5460 kg) per arm asdf dsf dsf dsf | Request Info |

| Model 1 Here | 1 | 55″ – 239″ (1440 – 6000 mm) | 1000 – 12000 lbs (454 – 5460 kg) per arm | Request Info |

| Model 1 Here | 1 | 55″ – 239″ (1440 – 6000 mm) | 1000 – 12000 lbs (454 – 5460 kg) per arm | Request Info |

| Model 1 Here | 1 | 55″ – 239″ (1440 – 6000 mm) | 1000 – 12000 lbs (454 – 5460 kg) per arm | Request Info |

| Model 1 Here | 1 | 55″ – 239″ (1440 – 6000 mm) | 1000 – 12000 lbs (454 – 5460 kg) per arm | Request Info |

| Model 1 Here | 1 | 55″ – 239″ (1440 – 6000 mm) | 1000 – 12000 lbs (454 – 5460 kg) per arm | Request Info |

| Model 1 Here | 1 | 55″ – 239″ (1440 – 6000 mm) | 1000 – 12000 lbs (454 – 5460 kg) per arm | Request Info |

| Model 1 Here | 1 | 55″ – 239″ (1440 – 6000 mm) | 1000 – 12000 lbs (454 – 5460 kg) per arm | Request Info |

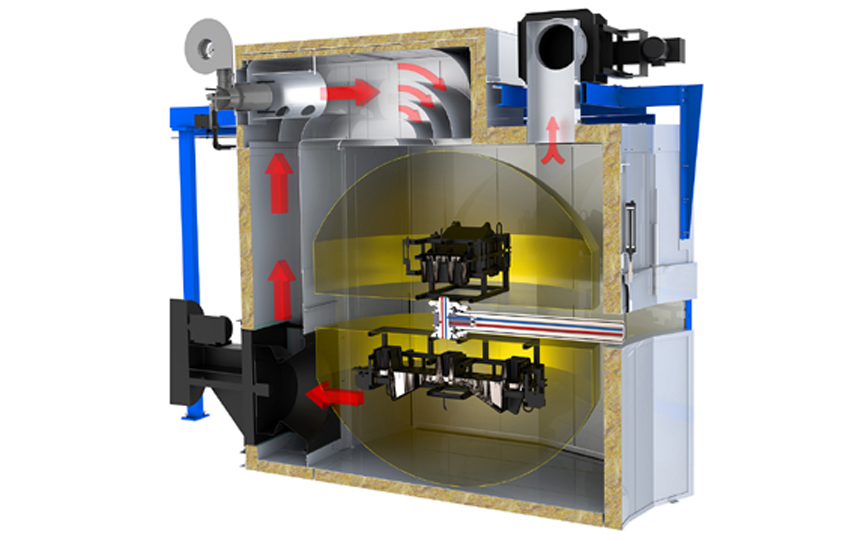

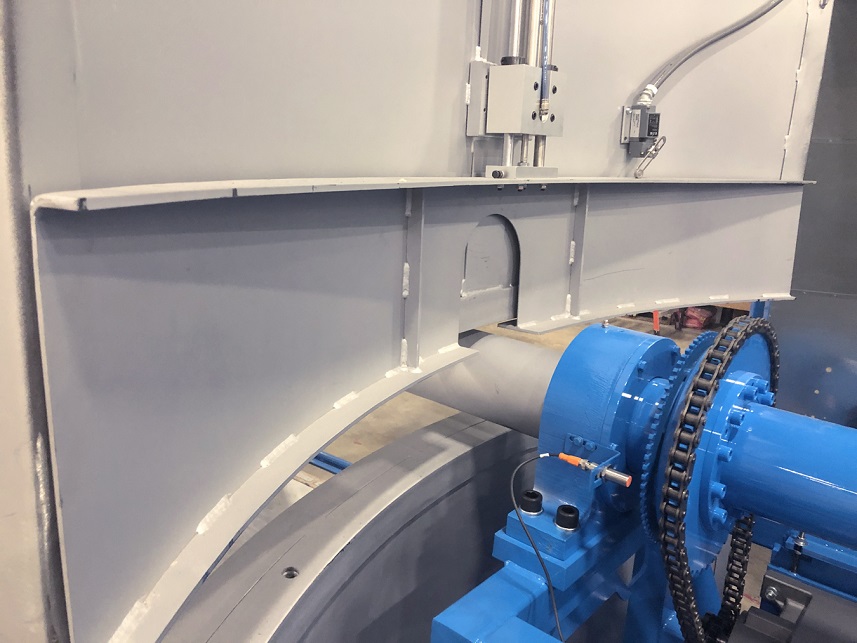

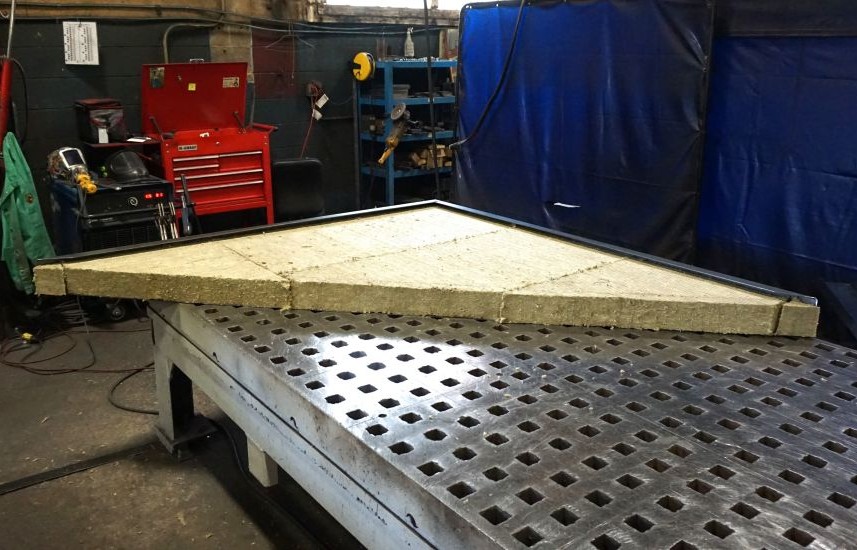

Oven Systems & Components

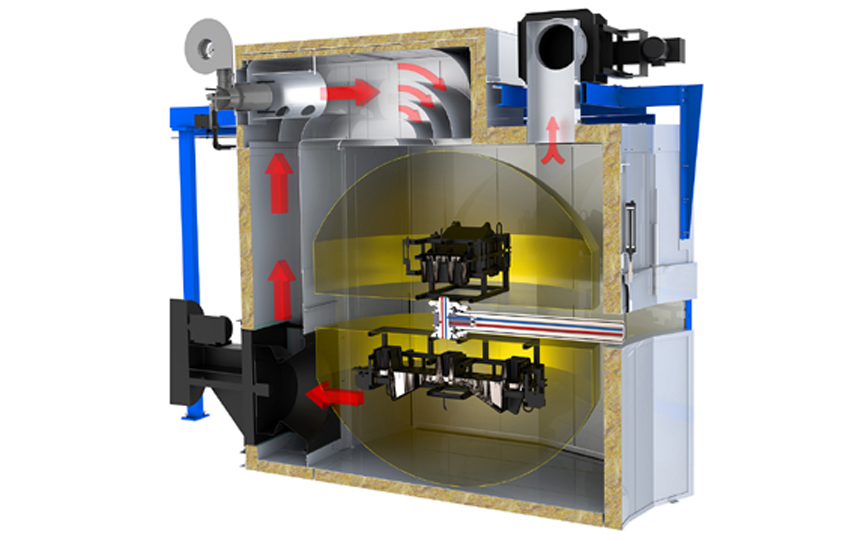

Ferry RotoSpeed ovens are designed & engineered to provide molders with energy savings, fast cycles, quick recovery time and are integrated with RotoCure and IRT for energy and cycle reduction.

• Quick oven temperature recovery

• Fast cook cycles

• Efficient use of energy — savings of 10% gas with management of oven exhaust gas as standard

• Available heat exchangers to recuperate up to 25% of gas consumption

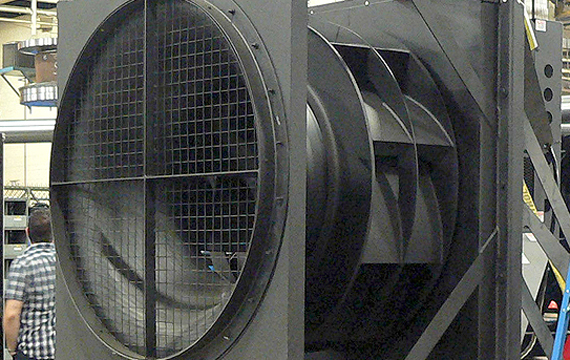

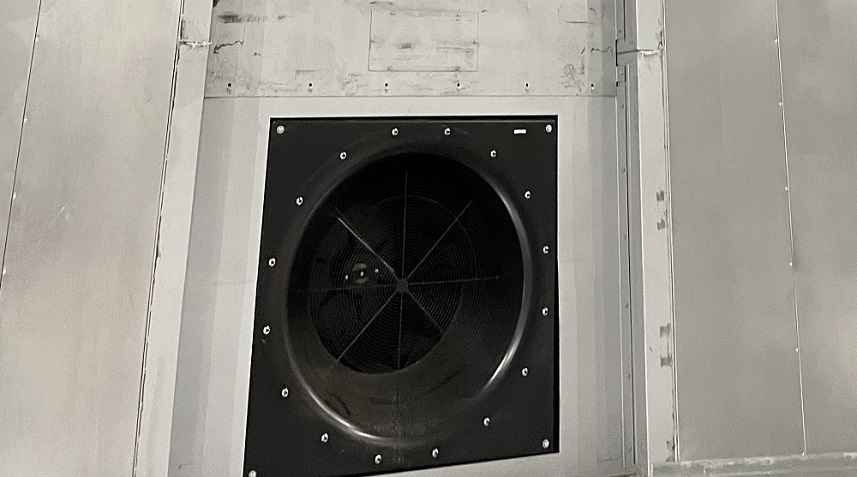

• Variable speed circulation fans to reduce heat loss when doors are open

A fuel type can be specified.

Replacement parts and systems are available as well as upgraded components for older machines.