Upgrades

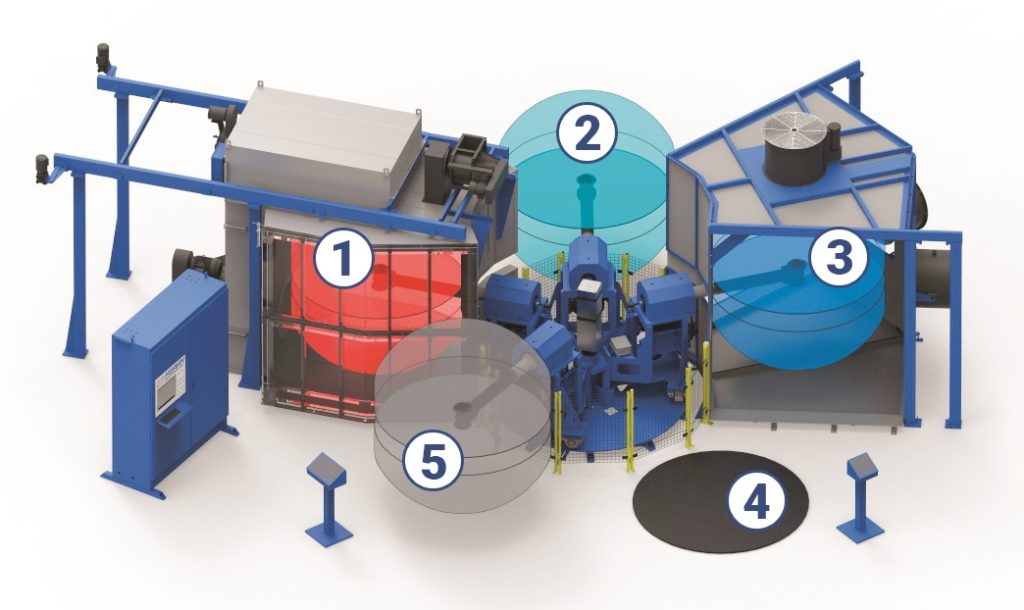

Ferry Industries, Inc., pioneered the four-arm, five-station independent-arm carousel machine for the rotational molding industry. RotoSpeed independent-arm machines (with each arm on a separate cart) provide a multiple-station arrangement for heating, cooling, and servicing. Each cart indexes about a center pivot post and shares a common load-bearing track.

The floor plan provides five process stations: 1. Oven 2. Pre-cool or Intermediate 3. Cooling 4. Unload 5. Load

- Oven

- Pre-cool or Intermediate

- Cooling

- Unload

- Load

These machines can be purchased with only one arm/cart. Up to three more may be added without mechanical modifications to the existing machine. Double ovens or double cooling stations are available initially or can be added later due to the modular layout of the RotoSpeed independent-arm concept. Custom design for these machines is available.

Models Available

| Model Name | # of Arma | Swing Ranges | Capacities | |

|---|---|---|---|---|

| Model 1 Here | 1 | 55″ – 239″ (1440 – 6125 mm) | 1000 – 12000 lbs (454 – 5460 kg) per arm asdf dsf dsf dsf | Request Info |

| Model 1 Here | 1 | 55″ – 239″ (1440 – 6000 mm) | 1000 – 12000 lbs (454 – 5460 kg) per arm | Request Info |

| Model 1 Here | 1 | 55″ – 239″ (1440 – 6000 mm) | 1000 – 12000 lbs (454 – 5460 kg) per arm | Request Info |

| Model 1 Here | 1 | 55″ – 239″ (1440 – 6000 mm) | 1000 – 12000 lbs (454 – 5460 kg) per arm | Request Info |

| Model 1 Here | 1 | 55″ – 239″ (1440 – 6000 mm) | 1000 – 12000 lbs (454 – 5460 kg) per arm | Request Info |

| Model 1 Here | 1 | 55″ – 239″ (1440 – 6000 mm) | 1000 – 12000 lbs (454 – 5460 kg) per arm | Request Info |

| Model 1 Here | 1 | 55″ – 239″ (1440 – 6000 mm) | 1000 – 12000 lbs (454 – 5460 kg) per arm | Request Info |

| Model 1 Here | 1 | 55″ – 239″ (1440 – 6000 mm) | 1000 – 12000 lbs (454 – 5460 kg) per arm | Request Info |

Ferry RotoCure Upgrades & Conversions

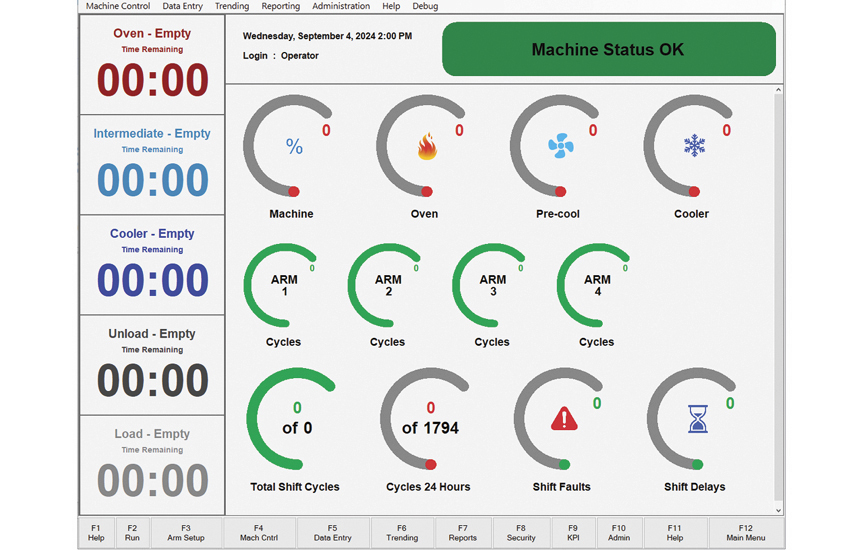

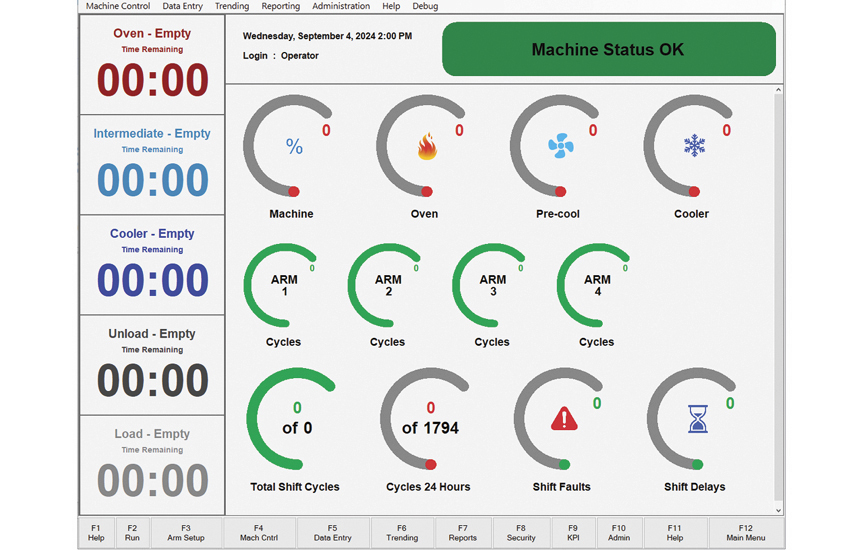

Ferry can Upgrade your older RotoCure Operating System to the latest RotoCure Process Management Control System technology and integrated programming features.

- PLC Upgrades

- KPI screen for quick overview of performance, look at shift, day, week or month

- Gas Usage Tracking

- InfraRed Thermometry (IRT) Set-up & programming integration

- Multi-layer (shot) programming in the cure recipe set-up

- Rocking programming to build wall thickness in specific areas

- Arm Orientation – program step functions into the Cure Recipe

- Oven & Cooler Upgrades

Upgrade the Main Control Cabinet & RotoCure Operating System

Ferry can Upgrade your older main control cabinet & the RotoCure Operating System to the latest technology and integrated safety features.

- Newest RotoCure Process Management Control System

- PLC Upgrades

- InfraRed Thermometry (IRT) Set-up & programming integration

- Oven & Cooler Upgrades

- Gas Usage Tracking

- Heat recovery systems

- High-efficiency, low-noise fans

- Auxiliary Fans, with water mist

- Arm & Carriage Upgrades

- Arm Orientation Upgrade

- Gearmotor & Drive Upgrades