RotoLoad Powder Dispensing Systems

The RotoLoad Powder Dispensing System is an automatic powder weighing and dispensing system that will quickly, safely and cleanly dispense your powdered PE directly into the molds that are mounted on your rotational molding machine.

Utilizing the RotoLoad will assure accurate product weights resulting in: • Consistent product weights • Dependable product wall thickness • Reduce powder spillage • Cleaner work environment • Less material contamination

Removing manual weighing and transporting will: • Save time; dramatically cut labor costs • No more buckets to load and transport • Minimal machine-operator back issues • Eliminate under-weight & over-weight product • Reduce scrap

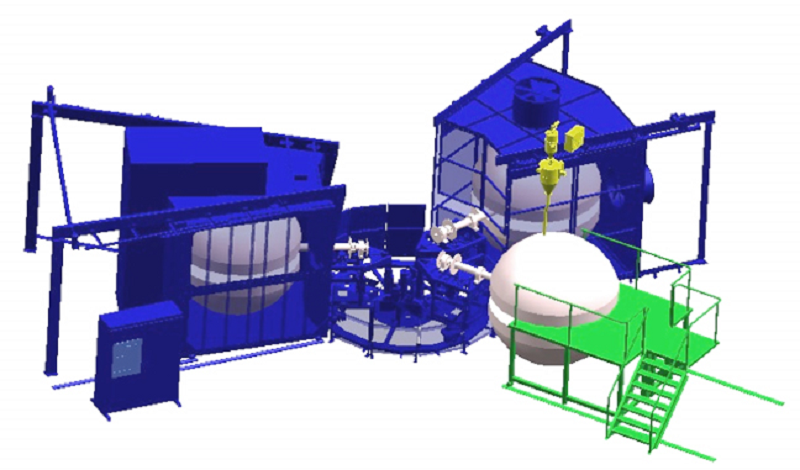

There are two configurations of the RotoLoad; the INTEGRAL and CENTRAL Systems.

The INTEGRAL System features a stand-alone, self-contained hopper complete with its own individual vacuum loader and filter system. The powder source (typically a gaylord or day bin) for the INTEGRAL system will be positioned in relatively close proximity to the RotoLoad. We offer the INTEGRAL system with powder capacities of 50-lb, 150-lb or 300-lb. Depending on the hopper size, the RotoLoad can drop powder at approximately 6-lbs/second (360-lbs/minute) and re-load at approximately 15- to 20-lbs/minute. Accuracy of about 1/10th of 1% is achievable.

The CENTRAL System utilizes a floor-mounted vacuum-pump that is capable of managing up to six (6) separate RotoLoad Powder Dispensing Systems. The floor-mounted vacuum pump provides enough power to feed each RotoLoad from a much greater distance such as a remote powder room or silo and includes its own control panel and stand-alone filter. The CENTRAL system will drop powder at the same rate as the INTEGRAL systems, but will re-load much faster at approximately 50-lbs/minute. Of course, the CENTRAL system may be equipped with any combination of the various sizes of vacuum weigh hoppers; the 50-lb, 150-lb or 300-lb.

Multi-Unit Dispensing System and Operator Pendant

Multiple Units on a Common Frame as a Dispensing Station